Products List

-

Stadea Diamond Cup Grinding Wheel - Resin Filled - for Granite Stone Quartz Concrete Grinding - Sizes 4 Inch, 5 Inch - Series Super A

STADEADCWD04SPRARP58PP$64.99 - $229.99Stadea Series Super A - Resin Filled Continuous - Diamond Cup Grinding Wheel - Designed for chip free, faster, low cost grinding of Granite Quartz Marble Concrete Other hard surfaces Available Grits 4 Inches 5 Inches Available... -

Stadea Diamond Cup Grinding Wheel 4" for Granite Quartz Concrete Grinding Sanding, Series Ultra A

STADEADCWD04ULTARC58PP$34.99 - $239.99Stadea Ultra A - Resin-Filled Continuous Diamond Cup Grinding Wheel for Granite Quartz Stone Concrete Grinding Stadea Series Ultra A - 4 Inch or 5 Inch resin-filled continuous diamond cup grinding wheel is designed for Granite, Quartz, Enginnered Stone,... -

STADEA 4" Diamond Concrete Grinding Cup Wheel For Stone Granite Marble Sanding

STADEADCWD04STDA00581P$47.99RRP: $69.99STADEA professional grade 4" or 105 mm Diamond cup wheel for Granite Marble, Concrete, Tiles, stone grinding polishing etc with arbor 5/8" 11. These cup wheel diamond grinding wheels for concrete works great on Granite, Marble, Concrete, Tiles, stone etc... -

STADEA Diamond Grinding Wheel Cup Wheel for Concrete Stone Granite, 4 Inch Series Super C

STADEADCWD04SPRC00581P$59.99RRP: $99.99STADEA professional grade 4" or 105 mm Diamond cup wheel for Granite Marble, Concrete, Tiles, stone grinding polishing etc with arbor 5/8" 11. These cup wheel diamond grinding wheels for concrete works great on Granite, Marble, Concrete, Tiles, stone etc... -

Stadea Diamond Cup Grinding Wheel for Granite Quartz Concrete Grinding Sanding - 6", 7" - Coarse Medium Fine - Series Ultra A

STADEADCWD07ULTARC58PP$124.99 - $479.99STADEA Resin Filled 6" / 7" Diamond cup grinding wheel for chip free aggressive sanding of Granite Quartz Marble, Concrete, Tiles, stone grinding with 5/8" 11. These cup wheel diamond grinding wheels for concrete works great on... -

Stadea 7 Inch Dust Shroud with Vacuum Attachment for Angle Hand Grinder

STADEAGDSR07STDA00031P$49.99Stadea Series Standard A - DSD102A, 7 Inch Dust Shroud for Hand Angle Grinders surface grinding, floor grinding dust collection. It is designed for ease of use, control and durability and minimizes and contains the dust exposure... -

Stadea Diamond Cup Grinding Wheel Turbo 4" for Stone Concrete Quartzite Grinding Sanding - Series Ultra A, Turbo

STADEADCWD04UATBRC58PP$77.99 - $219.99Stadea Ultra A - Resin-Filled TURBO Continuous Diamond Cup Grinding Wheel for Stone Quartzite Quartz Stone Concrete Grinding Stadea Series Ultra A Turbo - 4 Inch resin-filled continuous diamond cup grinding wheel is designed for Granite, Quartz,... -

STADEA Diamond Cup Grinding Wheel for Stone Concrete Marble Stone, 5 Inch Series Super C

STADEADCWD05SPRC00581P$72.99RRP: $119.99STADEA professional grade 5" or 125 mm Diamond cup wheel for Granite Marble, Concrete, Tiles, stone grinding polishing etc with arbor 5/8" 11. These Diamond cup wheel grinding wheel works great on Granite, Marble, Concrete, Tiles, stone etc. STADEA Super... -

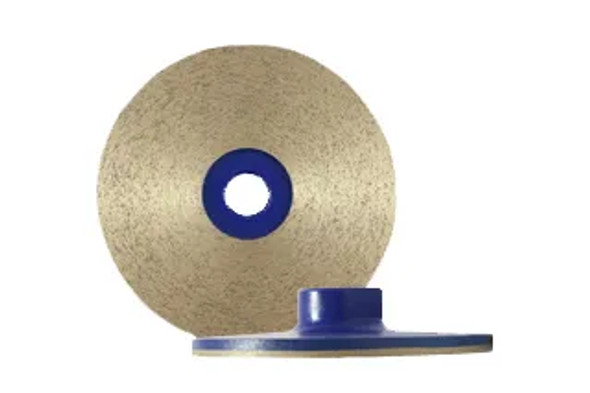

Stadea Diamond Convex Cup Grinding Wheel 4" for Granite Quartz Concrete Grinding Sanding, Series Ultra A

STADEADCCD04ULTARP58PP$79.99 - $219.99Stadea Ultra A - Resin-Filled Continuous Diamond Convex Cup Grinding Wheel for Granite Quartz Quartzite Stone Concrete Grinding Stadea Series Ultra A - 4 Inch resin-filled continuous diamond convex cup grinding wheel is designed for Granite, Quartz,... -

Stadea Grinder Dust Shroud 5" for Angle Grinders Hand Grinders

STADEAGDSD05STDA00021P$27.99Stadea Grinder Dust Shroud 5" for Angle Grinders Hand Grinders Stadea Series Standard A - DSD101A, 5 Inch Hand Angle Grinder Dust Shroud for surface, floor grinding dust collection. It is designed to minimize and contain the dust exposure... -

Weha 4" Pitbull Hybrid Diamond Resin Cupwheel Rigid Aluminum Wet/Dry

WehaDCWD-WEH-04PITBUL-PPG$41.994" Pitbull Hybrid Diamond Resin Grinding Cupwheel Rigid Aluminum Wet or Dry Key Features: Hybrid Resin Bond: Harder bond than traditional resin polishing pads Performs like a resin-filled diamond cup grinding wheel Grinds and shapes with zero chipping... -

Stadea Diamond Cup Grinding Wheel 4" for Quartzite Granite Quartz Petrified Wood Agate Concrete Grinding Sanding, Series Ultra G

STADEADCWD04ULTGRC58PP$79.99 - $229.99Resin-Filled Continuous Diamond Cup Grinding Wheel for Quartzite Granite Hard Stone Grinding Stadea Series Ultra G - 4 Inch resin-filled continuous diamond grinding wheel is designed for hard material, Quartzite, Granite, Petrified Wood, Agate grinding... -

Apexx Full Surface 4 Inch Diamond Cup Wheel

APEXXDCWD-APE-04COARSE-PP$89.99Apexx 4 Inch Diamond Cup Wheel Key Features • The 4 inch diamond cup wheel features a 1/8" full diamond face delivers exceptional coverage and durability.• Super-soft bond ensures fast, controlled performance on dense surfaces.• Ideal for... -

Stadea 4" Micro Cut Diamond Cup Wheels for Porcelain Grinding - Resin Filled - Series Super P

STADEADCWD04SPRPMC581P$84.99RRP: $89.99 -

Stadea 4" Miter Grinding Diamond Cup Wheels for Granite, Quartzite, Quartz 45 Cuts - Resin Filled - Series Super A

STADEADCWD04SPRAMI581P$74.99RRP: $89.99 -

STADEA 5" Diamond Cup Wheel / Stone Grinding Wheel for Sanding Grinding Concrete Stone

STADEADCWD05STDA00581P$59.99RRP: $89.99STADEA professional grade 5" or 125 mm Diamond cup wheel for Granite Marble, Concrete, Tiles, stone grinding polishing etc with arbor 5/8" 11. These Diamond cup wheel grinding wheel works great on Granite, Marble, Concrete, Tiles, stone etc. STADEA... -

Cyclone Diamond Cluster Grinding Wheel

CycloneDCWD-CYC-04-CLUSTER-PP$73.45Cyclone Diamond Cluster Grinding Wheel The Cyclone Diamond Cluster Grinding Wheel uses diamond cluster points to rip away epoxy and fiberglass backing with ease. Flat tip leaves a smooth finish for easy surface preparation Great for removing resin... -

Xpeed 4 Inch Vacuum Brazed Diamond Cup Grinding Wheel

XpeedDCWD-XPE-04-PP$63.50 - $66.50Xpeed 4 Inch Vacuum Brazed Diamond Cup Grinding Wheel Type: Wet or Dry usage Application: • Ideal for Natural Stone using a 4 inch diamond cup wheel• Suitable for Engineered Stone with a vacuum brazed grinding wheel• Effective on... -

Cyclone S Rockbuster Resin Cup Wheel

CycloneDCWD-CYC-0430G-ROCKBUS-PP$79.50Cyclone S Rockbuster Resin Cup Wheel Dust-Free Performance Eliminate airborne particles and jobsite hazards. Enjoy a dramatically cleaner operation compared to traditional grinding wheels. The resin cup wheel ensures a dust-free environment, offering... -

Diamax Cyclone 4 Inch Diamond Cup Wheel

CycloneDCWD-CYC-04-ULTRA#PP$62.50Cyclone Ultra Cup Wheel Overview • Designed for smooth, chip-free grinding with fine diamond grit.• Ideal for prepping seam joints, miter cleanups, and beveled edge finishes.• Lightweight construction suitable for pneumatic polishers... -

Stadea 4" Micro Cut Diamond Cup Wheels for Decton Grinding - Resin Filled - Series Super D

STADEADCWD04SPRDMC581P$84.99RRP: $89.99